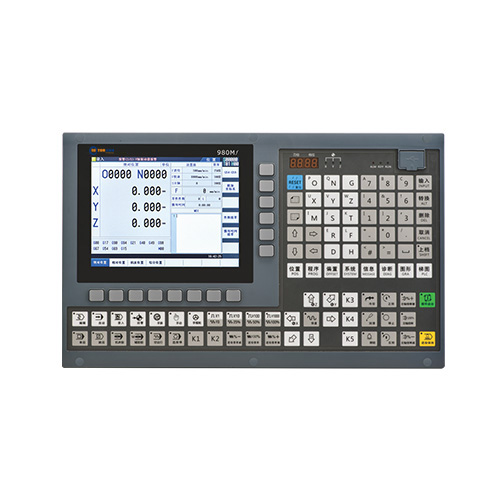

MLT980TA adopts 8.4 "color LCD, new appearance design, horizontal,

vertical two structural forms. Maximum control of 5 axes (including

C-axis), minimum instruction unit 0.1μm. Handal trial, teaching

programming, Debug wizard, parallel PLC axial control, etc., supports

drilling tapping, cylindrical interpolation, polar coordinate

interpolation, polygonal turning, etc. The interface is fully compatible

with MLT980TDC, which is better than MLT980TDC. MLT980TA supports

absolute And the adaptation of the incremental servo device is the

choice of popularity of the number control lathes!

Main technical characteristics

8.4 "Color LCD, new appearance design

14 separate software keys, easy operation

With automatic tool offset function, support automatic knife detector adaptation

Have fun in teaching programming, hand test, debugging wizard, programming debugging is simple and efficient

Have a control function, car, milling, etc. of polygonal cars,

cylindrical interpolation, polar coordinate interpolation, cars and

milling

Support parallel PLC axial control, zero-cost implementation of the indexing table, rotating material frame, truss, etc.

Support interface custom, built-in multi-PLC, personalized products easy to create

With additional panel fast connection interface, it can greatly simplify the connection of additional panels.

Unlimited time-time shutdown function, refusing arrears

Free adaptable absolute, incremental servo drive

|

Project

|

MLT980Ta

|

|

LCD

|

8.4

|

|

Maximum Control Rax

|

5-axis (including CS axis)

|

|

Maximum CS Axis

|

2

|

|

Analog Voltage

|

2

|

|

Minimum Instruction Unit

|

0.0001mm

|

|

Maximum Transmission Speed

|

60000 mm/min

|

|

Maximum Cutting Speed

|

30000 mm/min

|

|

Basic IO

|

32/32

|

|

Cylindrical Interpolation

|

yes

|

|

Polar Interpolation

|

yes

|

|

Polygon

|

yes

|

|

Automatic Tool Offset

|

yes

|

|

Panel structure

|

Integrated panel

|

|

Dimensions (width × height × Deep, unit: mm)

|

Horizontal

|

420×260×80

|

|

Vertical

|

260×420×80

|